PRODUCTS DISPLAY

About us

DongGuan J-KING Metals Co., Ltd

DongGuan J-KING Metals Co., Ltd isa company with full experiences of metal material in trading and manufacturing.

We are a qualified company with many international certifications.

With the professional gravity casting technical ability and high precision process technic and equipment,

we have been persistently cooperating with many Japanese , Taiwanese and overseas customers.

Focus on Industry

Factory Area

Global cooperative clients

Qualification certificate

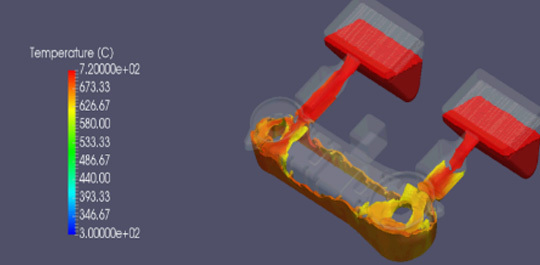

PROCESS

certificate

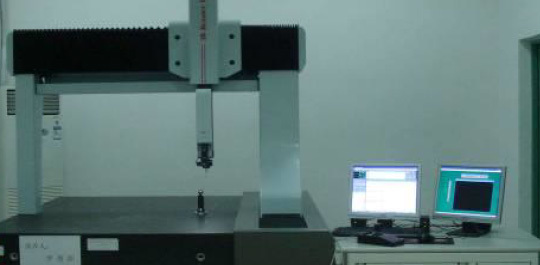

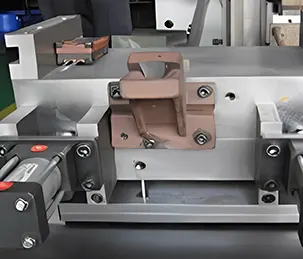

EQUIPMENT

Casting Equipment

View more+

Inspect equipment

View more+

Processing/Other Equipment

View more+Specialized in all kinds metal casting

News Center

No data